What exactly is PPS?

The raw material polyphenylene sulphide (PPS) is a high-performance plastic at the top of the plastics pyramid. It is characterised by its very good mechanical properties and maximum chemical resistance at continuous operating temperatures of up to 150°C. With PPS, we are able to realise very close tolerances without mechanical post-processing, even during high-volume production.

The challenge of processing PPS

PPS requires extremely high processing temperatures of up to 360°C and mould temperatures of up to 160°C in injection moulding. These are extreme parameters that continually pose significant challenges to our construction and development department, as well as to our mould construction and manufacture. In addition to this, PPS has a strongly corrosive effect on machine components and injection moulds, has a tendency to burr formation and has a tight processing window. However, these factors are not a problem for our experienced team of specialists. Our processes result in extremely precise components and parts made of high-performance plastics that meet our customers’ highest demands for quality.

PA (polyamide) and PPS (polyphenylene sulphide)

A brief comparison: in contrast to conventional PA, PPS has higher mechanical strength and a lower creep tendency. Furthermore, PPS can withstand higher continuous operating temperatures and service temperatures of up to 230°C. The hydrolysis resistance and low tendency towards water absorption mean that parts made of PPS have a high dimensional accuracy, even when used in damp and hot conditions. These are properties that standard PA cannot compete with.

Absolutely sustainable: PPS as a substitute for metal

Taking both economic and ecological factors into account, PPS is a suitable substitute for aluminium, considering the ever increasing demands that technical components now have to meet. The operating temperatures are higher, and the standards regarding precision and functional integration are also increasing. PPS fully meets these standards. Components made of PPS are more lightweight and durable; this is how, for example, they contribute to lightweight construction and weight reduction in automotive engineering and help to save fuel and CO2.

Currently, components and product systems made of PPS are most frequently used in the automotive and electrical sectors. This high-performance plastic is also of great interesting in the fields of energy (batteries, fuel cells, solar collectors), refrigeration and air-conditioning, machine construction and the chemical industry (pumps, valves, mechatronics).

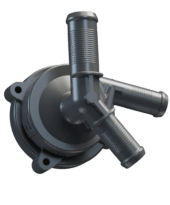

Our PPS products – core competency in injection moulding

Our manufacturing processes result in functionally integrated, extremely precise technical parts made of PPS, which our OEM and tier 1 automotive customers have found highly satisfactory for decades. Depending on the requirements of the end product, the PPS material is strengthened with 30% to 40% glass fibre, or comes with 30% mineral additives.

Our best-selling products include plastics for engines, ventilation systems, circulating water pumps, auxiliary heating systems and chassis in general, cooling pumps and fuel injection pumps, both for powertrains in the automobile sector and for thermal and fluid management. One of our decisive core competencies is hybrid injection moulding (insert technology) in combination with PPS. This means that even more functions can be integrated cost-effectively into a component. We injection-mould components such as thread inserts, contacts or axes – expertise that sets us apart from our competitors.

Back to overview Masterpiece Line

Masterpiece Line Pressure Sprayers

Pressure Sprayers Trigger Sprayers

Trigger Sprayers Bottles & Caps

Bottles & Caps Precision components made of high-performance plastics

Precision components made of high-performance plastics Innovative hybrid parts

Innovative hybrid parts