1. Refer to the Kläger Plastik user manual

Each sprayer purchased from us includes a user manual with information about preparation, use and safety. Please read it carefully and follow the instructions.

2. Decant any remaining liquid into its original container (if possible) after use and rinse out the compressed air sprayer with clean water or a suitable cleaning agent

This will protect the materials of the compressed air sprayer from the effects of the chemical liquids, extending its product lifespan.

Alternatively, the liquid can be transferred to a spare pressure sprayer container and sealed with a screw cap.

3. Contact our Chemical Application Center before filling new, unfamiliar liquids in the sprayer

Ensure that the type of resistance of your compressed air sprayer is also suitable for the intended contents.

Sebastian Keder (right), Head of Quality Management, and Ralf Knüttel (left), who has been working in quality management at Kläger Plastik for almost 20 years, are the specialists at our Chemical Application Centre and your contacts for individual advice on resistances.

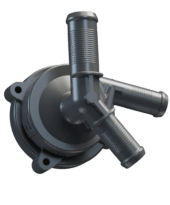

4. Carry out regular care and maintenance of the compressed air sprayer, particularly by greasing the pump piston O-ring (see the adjacent exploded-view drawing for the position of the O-ring in the sprayer)

It is important to use a suitable lubricant, since not all products are compatible with each type of resistance (e.g. only certain oils, such as pure silicone oil, should be used to grease EPDM seals; products containing mineral oils should not be used). Greasing ensures that the compressed air sprayer pump can move freely and remains fully functional.

5. Pay attention to environmental influences, the place where the product is used, and the workspace in general

- Protect the sprayer from extremes of heat and cold

If liquid is left inside the compressed air sprayer and it is then exposed to minus temperatures or even more extreme temperatures over a long period of time, the contents can freeze, depending on their composition.

In some cases, components of the compressed air sprayer can also be affected by frozen liquid, or even become irreparably damaged, resulting in a sprayer that no longer works. - Do not expose the compressed air sprayer to direct sunlight for long periods of time.

UV rays damage the molecular chains, making the plastic porous or brittle. They can also lead to discolouration.

6. In addition to the Kläger Plastik user manual, it is important to refer to the liquid manufacturer’s operation and safety instructions, plus their safety data sheet, before using the liquid

Non-compliance with the liquid manufacturer’s recommended mixture ratios can lead to a reduction in the product lifespan of the compressed air sprayer due to the increased concentration of the substances used.

7. Check that the nozzle and the suction strainer at the end of the tube are free of deposits

The suction strainer prevents coarse contaminants that may be in the filling liquid from entering the liquid channel of the compressed air sprayer and obstructing or clogging it. However, it is possible that some product ingredients may crystalize and clog the suction strainer or nozzle. If the strainer or nozzle are clogged, they are best cleaned with compressed air.

Back to overview

Masterpiece Line

Masterpiece Line Pressure Sprayers

Pressure Sprayers Trigger Sprayers

Trigger Sprayers Bottles & Caps

Bottles & Caps Precision components made of high-performance plastics

Precision components made of high-performance plastics Innovative hybrid parts

Innovative hybrid parts