The result: our customers receive ready-to-use components for speedy further processing, and for attractive, marketable terms. This is how we, as a family-run medium-sized business, stay true to the “Made in Germany” seal of quality. After all, this future-looking strategy guarantees consistently high quality and creates long-term process stability.

- Several large assembly lines and additional facilities for manufacturing spraying systems

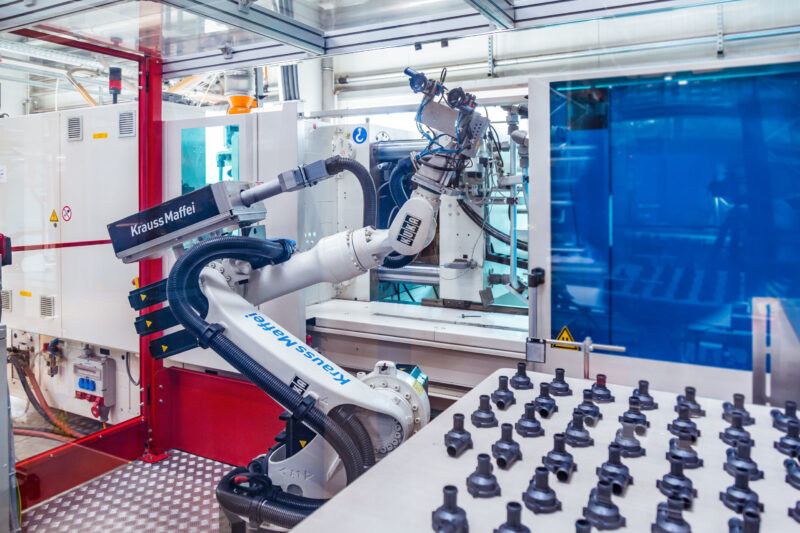

- Automation solutions for the manufacture of metal inserts (hybrid injection moulding or insert technology)

- Automated sorting upon customer’s request

- Various robot and automation systems on the injection moulding machines, including for precisely positioned removal (e.g. in trays)

- Various automated quality control systems (including optical controls via camera, via vacuum, leak and burst testing systems, weight controls or laser engraving for product tracing)

Masterpiece Line

Masterpiece Line Pressure Sprayers

Pressure Sprayers Trigger Sprayers

Trigger Sprayers Bottles & Caps

Bottles & Caps Precision components made of high-performance plastics

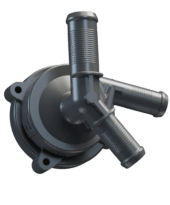

Precision components made of high-performance plastics Innovative hybrid parts

Innovative hybrid parts